how to make homemade hollow blocks and concrete

How to Make Hollow Blocks - Pinoy Builders

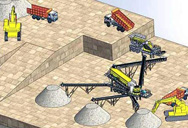

2021.9.23 There are four fundamental processes in creating hollow blocks: mixing, molding, curing, and cubing. Some plants are capable of making more than 2,000 blocks per hour. Other manufacturing plants also precast concrete blocks products like flat paver stones and decorative pieces of landscaping like lawn endings. Find a comfortable place.

More

Make Your Own Concrete Blocks – Mother Earth News

1975.1.1 Home Gardening DIY Blogs Ideas. Make Your Own Concrete Blocks. By William P. Earwood. These easy-to-follow steps show how to make your own concrete blocks. A helpful diagram is provided. I...

More

The Complete Guide To Hollow Concrete Blocks! FACTOFIT

2024.4.25 Build Strong, Build Smart with Jindal Mechno Bricks. Understanding Hollow Block Bricks. Hollow block bricks, commonly known as hollow blocks, are precast concrete blocks. They are distinguished by their hollow centers, as

More

How to make heavy-duty concrete blocks with

How to make heavy-duty concrete blocks with your own hands – Superdurables. by Steven Hancock. Why don’t you make the heavy-duty cement blocks you need with your own hands? This is a very simple

More

Concrete Hollow Blocks - The Ultimate Guide - Block Machine

2020.4.30 How to produce concrete hollow blocks? What hollow bricks can your brick machine produce? The main features of concrete hollow blocks. Grade standard and marking of hollow brick. Technical requirements of concrete hollow brick. Raw material standards. Construction requirements of concrete hollow brick. How to produce concrete

More

Everything You Need To Know About Concrete Hollow Blocks

5 天之前 Yes, hollow concrete blocks are very good insulators. The hollow spaces within these concrete blocks reduce the amount of solid material through which heat can travel. This therefore helps to keep a building warm in the cold months and cool when summer reigns. The hollows make hollow concrete blocks good sound insulators too. This

More

Hollow Concrete Blocks Guide Reinforced For Superior

In this guide from Building Materials Nations, we’ll explore the benefits offered by building with hollow concrete blocks, the sizes and cost of hollow concrete blocks, and the ways they can be used in both construction and gardening.

More

Concrete Blocks in Architecture: How to Build

2024.4.9 Broadly speaking, its manufacturing involves four processes: Mixing: After weighing, the appropriate amounts of water, gravel, and dry cement are mixed, followed by the addition of water....

More

Make Your Own Concrete Blocks – Mother Earth News

1975.1.1 Call 1-800-234-3368. Make your own concrete blocks to save money and bring out the builder in you. Originally published as "Feedback on ... Concrete Block Construction" in the January/February ...

More

9 Ways to Make Foam Concrete Blocks - wikiHow

2023.11.24 Mix the water and cement together. Add 5 gallons of water to your cement mixer or wheelbarrow. Then, add the cement mix. For best mixing results, add the first half of your 94lb bag of concrete mix to your mixer or wheelbarrow. Mix until the cement is even throughout the whole thing and then add the last half of the bag.

More

Hollow Blocks: Classifications, 12 Technical Details,

2023.9.25 3. Classification of Concrete Blocks. The hollow concrete blocks can be categorized into the following four types: 1. Grade ‘A’ ( Hollow ) These are load-bearing units and can contain the lowest block density

More

How concrete block is made - material, manufacture, used,

The first hollow concrete block was designed in 1890 by Harmon S. Palmer in the United States. After 10 years of experimenting, Palmer patented the design in 1900. ... The concrete commonly used to make concrete blocks is a mixture of powdered portland cement, water, sand, and gravel. This produces a light gray block with a fine surface

More

How to make heavy-duty concrete blocks with your own hands

If you have 5 molds and want to pour the mixture on all of them at the same time, you need to estimate how much mixture each hole will need to film a concrete brick. To mix, put 2 parts of fine sand and 1 part of fine gravel and then add 1 part concrete cement. Mix them with the spade and dose with water while the mixing continues.

More

Concrete Blocks in Architecture: How to Build With This

2024.4.9 2. Prepare the mortar and spread it onto the previously moistened strip footing, covering the width of a block. The initial layer should be 1 inch (2.5 cm) thick. 3. Begin placing the blocks ...

More

How to Build a Drywell With Hollow Concrete Blocks

2023.4.24 Fill the hole the next day with water to a depth of 300 mm. Measure the time in seconds it takes for water to drop in level from 75 % full (225 mm) to 25 % full (75 mm). This is a drop of 150 mm. The test should be carried out at least three times in total with each of the holes. Take the average value for each hole.

More

Everything You Need to Know About Concrete Hollow Blocks

2022.6.8 A hollow-core concrete block is generally more than 50% solid. Hollow concrete blocks are available in full and half sizes. The rectangular full-size bricks have two cores. Half-size blocks feature a single core and are cubical in shape. 100 mm x 200 mm x 400 mm, 150 mm x 200 mm x 400 mm, and 200 mm x 200 mm x 400 mm are all

More

Different Types of Concrete Blocks—How To Tell Them Apart

5 天之前 Hollow vs. Solid Concrete Blocks. There are two primary types of concrete block: hollow and solid. Hollow concrete blocks are manufactured with holes in them and are sometime referred to as Knock Out Block. They are lighter and are often used in building large structures because the holes reduce dead load and make it easier to run wiring ...

More

√ Hollow Blocks Price List and Size Philippines 2024

The price varies. Here’s a price list of hollow blocks price with standard size of hollow blocks in the philippines. Strength. Dimension. Price (in ₱) Ordinary. 40 cm x 20 cm x 4 inches. 12.00. 40 cm x 20 cm x 5 inches.

More

Home Garden Projects - Artsy Pretty Plants

2024.5.14 The home and garden tutorials include detailed step-by-step instructions, plenty of details, and essential tips. Advice I typically include: The advantages of DIY projects, including cost savings and personal satisfaction. Considerations for choosing the right projects based on skill level, budget, and time constraints. Gathering the necessary ...

More

Concrete Block Making Machine - Global Supply LONTTO

4 天之前 QT4-18 concrete block machine is an automatic machine ideal for concrete brick production, including paver and interlocking bricks. As a versatile hydraulic machine, it’s designed to produce a variety of concrete blocks, paver blocks, and hollow blocks. Tech data: Capacity: Solid Block: 49920pcs/8hours. Pallet size: 850x550mm.

More

Hollow Block Advantages Disadvantages of Hollow Block Hollow ...

2023.8.25 Hollow Concrete Block Size. Hollow concrete blocks made from Cement, aggregate, water is able to be produced in required size and shape by block making machine, as concrete masonry unit for building material, the common size is 4 inches, 6 inches, 8 inches, 10 inches, and 12-inch unit configurations. Advantages of Hollow

More

How to Make Concrete: 13 Steps (with Pictures) - wikiHow

2023.11.20 Fill a 5-gallon (18.9 l) bucket ¾ of the way with water and pour the water into the dry ingredients. Pour slowly so that the water doesn’t splash around, mixing in between and adding

More

Hollow Concrete Blocks in Saudi Arabia - ”Readymix.sa”

Features of Hollow Concrete Blocks. Hollow concrete bricks or blocks are typically made from a chemical admixture of Portland cement, mingled cement, different varieties of aggregates, crushed stones and water. They are also known concrete masonry units (CMU) in Saudi Arabia. Hollow blocks are lightweight, affordable, immensely durable ...

More

Design, Analysis and Development of Improved Hollow

2022.3.8 Abstract - This project report deals with the design and development of an improved hollow concrete block making machine. The machine lays a particular number of blocks over the platform and moves further to lay another set of blocks, so as to cover the casting platform, in a continuous casting process. This study attempts to solve the

More

How to Make Hollow Blocks - Pinoy Builders

2021.9.23 There are four fundamental processes in creating hollow blocks: mixing, molding, curing, and cubing. Some plants are capable of making more than 2,000 blocks per hour. Other manufacturing plants also precast concrete blocks products like flat paver stones and decorative pieces of landscaping like lawn endings.

More

Standard Specifications of Hollow and Solid

The concrete block — hollow (open or closed cavity) or solid shall be referred to by its nominal dimensions. The nominal dimensions of the concrete blocks are given below: Length : 400, 500 or 600 mm. Height :

More

How to Lay Concrete Blocks Hitchcock King

Lay the first block. Spread a layer of mortar about one inch thick on the foundation or base where you’ll place the first block. Position the block and gently press it into the mortar. Check for level and alignment. Use your spirit level to make sure the block is level in all directions.

More

Design, Analysis and Development of Improved Hollow Concrete Block ...

2020.3.26 Tianjin University of Technology and Education, Tianjin, China. Abstract - This project report deals with the design and. development of an improved hollow concrete block making. machine. The ...

More

Hollow Concrete Blocks Guide Reinforced For Superior

Hollow concrete blocks are typically used for any construction project where strength is a priority. To make load-bearing walls using hollow concrete blocks, the holes will need to be filled with both reinforcement bars, known as rebars, and liquid cement. Rebars will normally be made from steel, and reinforced to ensure long-term performance.

More

How to Make Concrete Block Molds HomeSteady

2017.7.17 Measure the board and make a mark every 2 feet. Cut the board into four 2-foot pieces at the markings. Using double-headed nails, attach the pieces into a box shape. This will be the block form. Double-headed are designed to be easier to remove than regular nails, which will make dismantling the form that much easier once the concrete sets.

More

The Complete Guide To Hollow Concrete Blocks! FACTOFIT

2024.4.25 Hollow block bricks offer a range of benefits that make them a preferred choice in modern construction: Reduced Weight: Their hollow centers make them lighter than solid concrete blocks, easing the burden on the foundation and framework of the structure, and facilitating easier and faster construction. Enhanced Insulation: The air

More