jaw crusher in india mining operations

Jaw Crusher - thyssenkrupp Industries India

Proven quality – great flexibility – easy operation. thyssenkrupp Jaw Crushers are used for Primary Crushing. The material is crushed by compressive shear forces. Flywheels with high moment of Inertia are generating high crushing energy compensate crusher peak

More

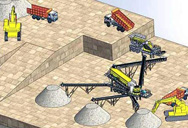

Application of Crushing in Mining - Picson Construction

We Engineer We Manufacture We Deliver Worldwide. Picson are Crushing Machine Manufacturers in India. A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.

More

Failure rate analysis of Jaw Crusher: a case study

2019.1.2 The present study has examined failures of jaw crusher and its components in a major mineral processing plant. The failure data of

More

Stone Crushers: A Technical Review on Significant Part of

2022.5.13 The importance of crushers in the mining industry declined with the introduction and resultant dominance of AG and SAG based circuits, but the recent ... India 6 Primary crusher Jaw crusher Design + Analysis Dynamic and kinematic analysis of all parts of the crusher has been done to improve its performance 2016 Abdulkarim et al. [15]

More

Jaw Crusher Diagram: Simplified Guide - JXSC

2024.2.18 A jaw crusher is an indispensable tool in the mining and construction industries, known for its power to fragment hard materials such as rock and minerals. Comprising type of jaw crusher—the robust Single-toggle and the efficient Double-toggle—these hefty machines operate on the principle of compressing materials between

More

“Design and Analysis of Swing Jaw Plates of Jaw Crusher

Problem Description. The objective of the present work is to study for a design and analysis of commercially available swing jaw plates that is 0.9 m (36 in.) wide with 304 mm and 51 mm top and bottom openings of jaw crusher. The finite element method is applied to the analysis of the swing jaw plate.

More

Below the surface: Setting up an underground

2014.4.1 Jaw crushers are the most common solution in underground applications when the throughput is below 1000 tonnes per hour, depending somewhat on the scalping solutions. Above 1000 tph, primary gyratory

More

The Role of the Jaw Crusher in the Mining Process: Efficient ...

The jaw crusher plays a critical role in this process, providing efficient material reduction and optimizing production. This article will discuss the importance of the jaw crusher in the mining process and how it contributes to the overall success of the operation.

More

Stone Crushers: A Technical Review on Significant Part of

2022.5.14 Jaw crusher. Cone crusher. Impact crusher. Aggregate production. 1 Introduction. Crushers are widely used equipment to reduce the large size rocks into stones finer than about 50–100 mm in size [ 1 ]. In infrastructure industry, these equipment are available in different capacities ranging from 0.1 ton/hr. to 50 ton/hr.

More

Below the surface: Setting up an underground

2014.4.1 Jaw crushers are the most common solution in underground applications when the throughput is below 1000 tonnes per hour, depending somewhat on the scalping solutions. Above 1000 tph, primary gyratory

More

How Does a Jaw Crusher Work? A Simple Guide - JXSC

A jaw crusher is a robust, essential and rugged crusher used primarily in mining and construction for the initial crushing of large rocks and ore. Positioned at the start of the crushing process, it uses compressive force between two jaw plates to break down large materials into smaller, manageable pieces. ... For large, heavy-duty operations ...

More

Jaw Crusher SpringerLink

2023.6.21 The movable jaw plate approaches the fixed jaw plate periodically to realize the functions of crushing, splitting, breaking, and impacting, thus to coarsely or mediumly crush materials with various hardness. It was invented by American E.W. Black in the 1850s. The specification of jaw crusher is expressed by the feed port width B and

More

Industrial Solutions Jaw crushers - ThyssenKrupp

2022.11.21 Single-toggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher frame by means of a toggle plate. The kinematics of this type of toggle system result in a higher capacity than that achieved with a double-toggle jaw

More

What Is A Jaw Crusher - MEKA

1.) Obtaining the size or surface area required for the use of the ore or material. 2.) Allowing ease of transportation and storage. 3.) Separating the different minerals contained within the ore and to release them from one another. 4.) Obtaining the size or surface area required for the enrichment stage.

More

Jaw Crusher - thyssenkrupp Industries India

Proven quality – great flexibility – easy operation. thyssenkrupp Jaw Crushers are used for Primary Crushing. The material is crushed by compressive shear forces. Flywheels with high moment of Inertia are generating high crushing energy compensate crusher peak loads. The main feature of Jaw Crusher is the enhanced kinematics of the ...

More

Nordberg® C160™ jaw crusher - Metso

Nordberg® C160™ jaw crusher is designed to be extremely reliable. Its equipped to meet the expectations of customers who run their primary crushing plants 24 hours a day. Based on customer experience and comprehensive testing, the critical areas of Nordberg® C160™ jaw crusher are protected against wear. The vital parts are also quickly ...

More

Understanding Types of Jaw Crusher: A Comprehensive

2024.2.6 Blake jaw crushers, also as double toggle jaw crushers, are characterized by the position of the pivot of the swing jaw, which is located at the top of the machine. This design allows for a larger feed size and a higher capacity, making it suitable for primary crushing. The motion of the swing jaw in a Blake crusher is predominantly vertical ...

More

What Is a Jaw Crusher? – Sandrock Mining

2023.2.27 A jaw crusher is a primary crusher used in crushing processes that involve large pieces of material. It is designed to reduce the size of the material for further processing or use. Jaw crushers are typically used in the mining, construction, and demolition industries. The jaw crusher has a fixed jaw and a moving jaw.

More

About US: V-Tech Makkers Jaw Crusher Manufacturer Company India

2017.3.20 About Us. V TechMakkers is one of the leading construction and mining equipment manufacturers in India. We are a pioneer in manufacturing high grade and unmatched crushing and screening equipments that help resolve our customers’ crushing needs. We have a rich experience of design and manufacturing excellence.

More

Hydraulic Rock Breaker Manufacturers in India

Our machines are safe for the workers who operate them and also saves time by doing the work faster and smoothly. We manufacture Rock Breaker, Hydraulic Breaker, Cone Crusher, Vibro Ripper, Jaw Crusher and 200 TPH Crusher Plant. Our mining machines are suitable for modern mining operations because they are more efficient, safer, precise, cost ...

More

Rock Crushers, Stone Crushers, Screening and Crushing

200 kW. Capacity (by hour) 330 - 960 mtph (364 - 1,058 stph) Feed opening. 1,300 x 1,130 mm (51 x 45 in.) mm. Motor power. 160 kW (250 hp) Sandvik crushing and screening equipment. Unrivaled jaw crushers, cone crushers, gyratory crushers, impact crushers and more for mining and construction applications.

More

Portable jaw crusher in India with best price - SBM Crusher

Portable jaw crusher is the convenient crushing unit used in mining site. It is designed for ease of travel and safe operation. Equipped with a Hydraulic Jaw Crusher and Grizzly Feeder, the portable jaw crusher plant is ideally suited for crushing hard quarried stone or demolition debris. It is a low profile, severe duty, high production ...

More

Jaw Crusher - an overview ScienceDirect Topics

The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. The capacity is primarily a function of: 1. crusher design characteristics such as width and depth of the crushing chamber, 2.

More

Jaw Crusher Working Principle – StudiousGuy

5. The productivity of a jaw crusher is quite low. 6. The range of the jaw is a constraint; therefore, only a confined amount of material can be fed to the machine. 7. The moveable jaw of the jaw crusher is highly susceptible to undergo wear and tear. Uses of a Jaw Crusher Mining. A jaw crusher is typically used in the mining of elements such ...

More

Nordberg® C Series™ jaw crushers - Metso

Nordberg® C Series™ jaw crushers are used as primary crushers in aggregates production, mining operations and recycling applications. ... The core of Nordberg® C Series™ jaw crusher is a pinned and bolted, non-welded frame construction that provides excellent fatigue strength. All the frame components are casted using an alloy developed ...

More

Understanding Jaw Crusher Parts and Their Functions - AGICO

2023.2.23 Introduction: Jaw crushers are powerful machines that are widely used in the mining, quarrying, and recycling industries. These machines are designed to crush large rocks and ores into smaller pieces for further processing. A jaw crusher consists of a fixed jaw and a movable jaw, with the latter being driven by an eccentric shaft that moves the

More

Stone Crusher and Cone Crusher Manufacturer in Gujarat, India

Crusher. Crushers are machines used to reduce the size of rocks, stones, and ore. They are often utilized in aggregates production, construction material recycling, and mining operations. PICS INTERNATIONAL offering covers different gyratory crushers, jaw crushers, cone crushers, and impact crushers – optimized for any size-reduction need.

More

10" x 16" Jaw Crusher - Mt Baker Mining and Metals

10″ x 16″ Jaw Crusher. This is a popular size for the smaller yard, grave marker shop, paver mfg. or serious ranch/farmer that does not use a crusher full-time. The throughput is respectable at 5-20 tons per hour, and the crusher will take up to 9″ feed material. We supply this machine with either a 20 hp 3 phase electric motor or a 20 hp ...

More

Jaw Crusher Working Principle - 911 Metallurgist

2021.5.6 The single-toggle type jaw crusher has been developed extensively. Because of its simplicity, lightweight, moderate cost, and good capacity, it has found quite a wide field of application in portable crushing rigs. It also fits into the small, single-stage mining operation much better than the slower Dodge type. Some years since this type

More

Selecting the right crusher for your operations

2020.3.19 Best suited for secondary crushing applications, cone crushers are designed to crush pre-sized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher. Cone crushers can

More

In-pit crushing and conveying technology in open-pit mining operations ...

2019.1.18 A dynamic model of the working mechanism of a compound pendulum jaw crusher with clearance is established by the Lagrange multiplier method (LMD) based on the L-N contact force model and modified ...

More

Jaw Crusher Manufacturers in Jhajjar - Pultvizor

L.N.C.T. Pulgaon Road, Durg, C.G., India 491001. info@pultvizor. 1800-309-3922. Available 10am - 7pm all days. Pultvizor is one of the leading Jaw Crusher Manufacturers in Jhajjar Providing Exceptional crushers catering to

More

Jaw Crusher - Eastman Rock Crusher

Capacity. 1-1120t/h. Output Size. 10-350mm. Jaw crusher is a compression style rock crusher, useful in crushing the medium-hard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit. Applications. mining, quarry, construction waste recycling, aggregate making, etc. Materials.

More

Crushers - All crusher types for your reduction needs - Metso

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

More

Jaw Crusher Diagram: Simplified Guide - JXSC

2024.2.18 A jaw crusher is an indispensable tool in the mining and construction industries, known for its power to fragment hard materials such as rock and minerals. Comprising type of jaw crusher—the robust Single-toggle and the efficient Double-toggle—these hefty machines operate on the principle of compressing materials between

More

safety guidelines for safe operation in jaw crusher

Here are some important guidelines to follow when operating a jaw crusher: 1. Start with the proper equipment: Before starting the jaw crusher, ensure that all required safety equipment is in place and operational. This may include safety

More

Jaw Crushers - Mt Baker Mining and Metals

Complete and ready to run including jaw crusher, belts, motor, full-enclosure guards, all integrated on a steel skid. Over-sized bearings and castings, robust construction, long-wearing cast manganese steel jaw plates. Optional steel stand. Sizes: 6”x 10” through 20” x 30″ jaw opening. Discharge size: ranges from 3/4” minus through 4 ...

More

Sandvik QJ341 Mobile Jaw Crusher – World Leading Jaw Crusher

1,200 x 750 mm (47 x 29 in.) Max. feed size. 650 mm (26 in.) Capacity. 400 mtph (440 stph) Sandvik QJ341 mobile jaw crusher is the ideal solution for a wide range of applications. Equipped with a C12 jaw crusher, a powerful and fuel-efficient engine, it is designed to tackle the most difficult operations. QJ341.

More

What Is a Jaw Crusher? Here's How It Works - Cutting

2021.2.18 A jaw crusher essentially crushes large rocks to a more usable size. They’re typically the first-line machinery used in the material reduction for several applications. This includes rock quarries, sand and gravel, construction aggregates, metallurgy, and chemical industries. Jaw crushers are specifically designed to handle

More